MonoLith™

Battery Platform

Bring the vehicle up in parallel. Pilot integration in ~10–16 weeks; certify your production pack on your timeline.

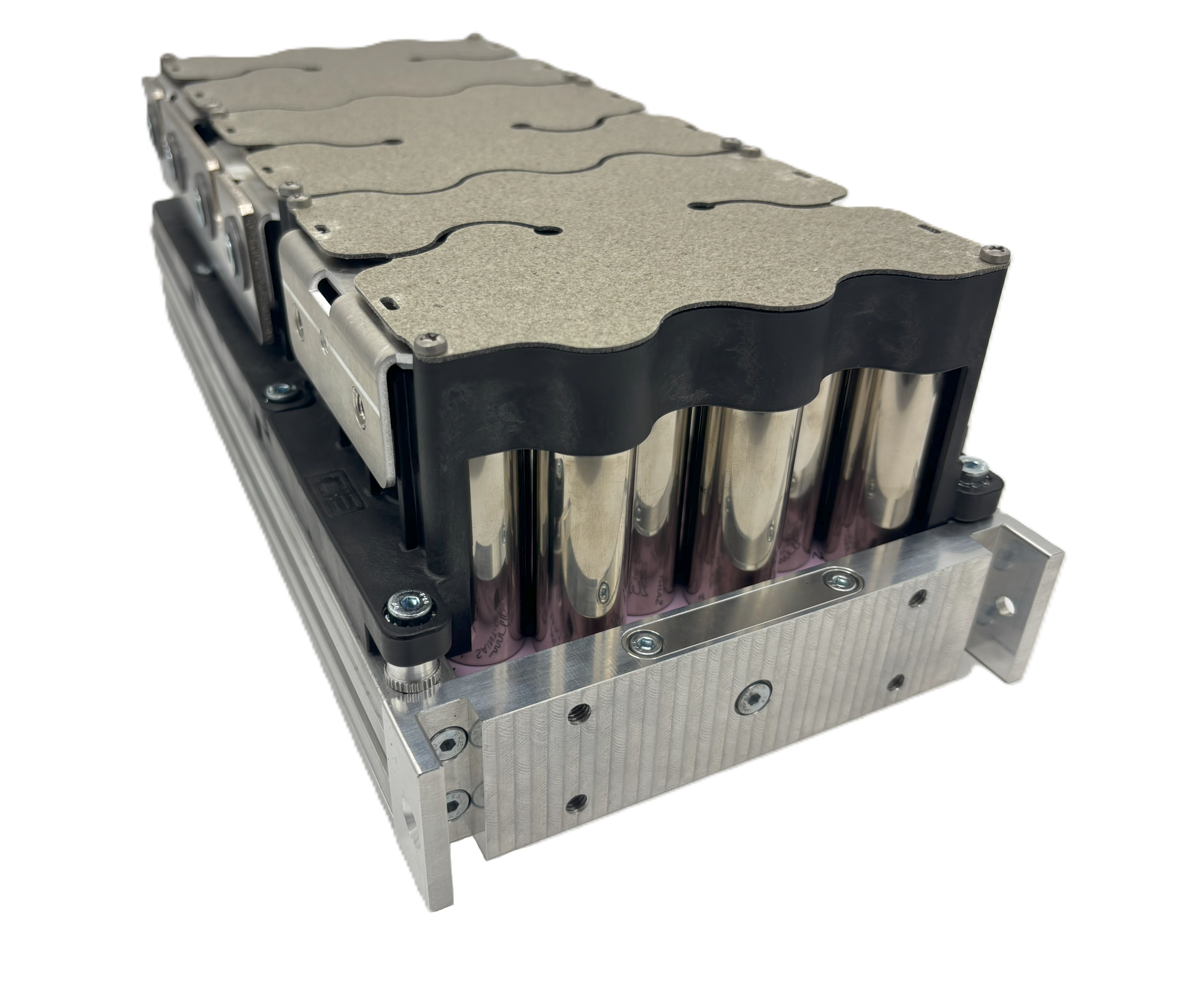

MonoLith™ Pack — Full Assembly

Structural cooling manifold, distributed BMS topology, and documented interfaces for rapid integration.

- • Documented mounting & electrical interfaces

- • UN 38.3 / UL 1973 program-ready documentation

- • CAN 2.0B (11/29-bit); DBC provided; VCU-master control.

Revolutionary Technology Platform

Our patented MonoLith™ platform represents a fundamental breakthrough in battery system architecture, delivering unprecedented scalability and cost efficiency for mission-critical applications.

Industry-First Patented Technology

Revolutionary modular architecture with proprietary scaling algorithms and thermal management systems.

Rapid Scalability Platform

Scale by 24-cell building blocks to the program's target energy — no redesign, no retooling, minimal lead time impact.

Minimal Tooling Investment

Standardized interfaces eliminate custom tooling costs. One platform serves multiple applications.

Accelerated Time-to-Market

Pre-validated modules and documented interfaces reduce integration time from months to weeks.

MonoLith™ in Action

Discover real-world applications and performance

Technical Specifications

Comprehensive technical data for engineering teams and system integrators.

Power & Energy

Physical & Environmental

Safety & Control

Controls & Communications

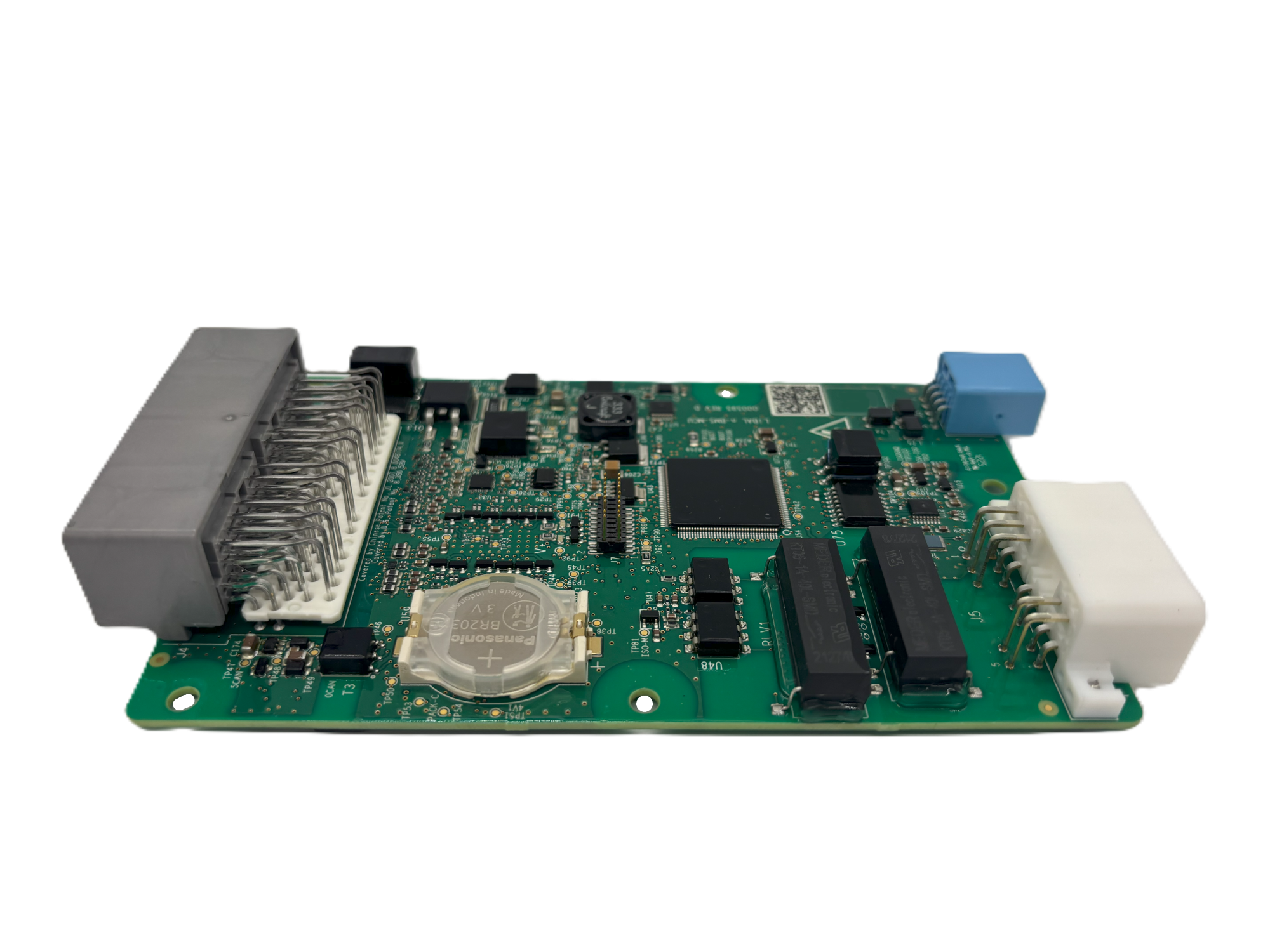

VCU-first control model: the BMS publishes limits & health on CAN and supervises HVIL, precharge, and contactors. Your VCU commands the loads within published limits. DBC is provided; message map & rates are documented in an ICD.

Integration highlights

- • CAN 2.0B (11/29-bit), up to 1 Mb/s

- • DBC provided for telemetry, limits, faults

- • VCU-master: BMS enforces safety, opens on fault

- • Configurable IDs/rates (documented ranges in ICD)

Engineering example (CAN 2.0B)

IDs shown as examples — your DBC carries the actual IDs and scaling.

# IDs shown as examples — your DBC carries the actual IDs, scaling, and endianness. 0x18FF50E5 BMS_Limits (20 ms) I_Charge_Max (A), I_Discharge_Max (A), V_Charge_Max (V), Flags 0x18FF51E5 BMS_Status (50 ms) Pack_V (0.1V), Pack_I (0.1A), SoC (%), Contactor_State, Precharge_State, HVIL # ---- Cell / Balance telemetry ---- 0x18FF60E5 VCU_Command (20 ms) Enable_Charge, Enable_Discharge, Charger_Ireq (A), Charger_Vreq (V) 0x18FF61E5 Cell_V_Page0 (50 ms) V0..V7 (mV) # 8 cells per page # ---- Protection / isolation ---- 0x18FF70E5 Isolation_Status (100 ms) Riso_Pos (kΩ), Riso_Neg (kΩ), ISO_Warn, ISO_Fault 0x18FF71E5 Faults_Latched (50 ms) Fault_Bitmap0, Fault_Bitmap1, Warn_Bitmap0, Warn_Bitmap1 # ---- Contactor / precharge detail ---- 0x18FF78E5 Precharge_Detail (50 ms) PC_State, PC_Timer (ms), V_Bus (0.1V), V_Pack (0.1V), dV (V), Inrush_Est (A) 0x18FF79E5 Contactors_Detail (50 ms) Main_Pos, Main_Neg, Precharge, Weld_Detect, HVIL_State # ---- Diagnostics / service ---- 0x18FF7AE5 Logger_Summary (500 ms) Max_Today_T (°C), Min_Today_V (mV), Trip_Count, Uptime (s) 0x18FF7BE5 Event_Trace (on evt) Event_ID, Severity, Arg0, Arg1 # Typical timing: telemetry 10–100 ms, balance/thermal 50–250 ms, version 2–5 s. See ICD for guarantees.

Structural & Tunable Thermal System

Leak certified, uniform ΔT, repeatable power, and easily fluid purge/bleed.

Structural

Stiffness + protection

Tunable

Per-array flow

Uniform ΔT

Repeatable power

Fast purge/bleed

Quick fluid maintenance

Leak Certified

24h N₂ hold

Structural, Tunable Cooling Array

Leak certified, uniform ΔT across arrays yields repeatable power and better cell life. Flow paths can be regulated as capacity scales.

Structural Manifold

Adds stiffness; protects flow passages from handling shock.

Per-Array Flow Control

Regulate distribution to maintain tight ΔT as arrays increase.

Pad Compliance

Thermal pad + torque pattern ensure full-area interface.

Fast Purge/Bleed

Service-oriented layout for quick fluid maintenance.

Leak Integrity (24h N₂)

Each manifold pressure-held with dry nitrogen; pressure-decay logged to serial.

Your ROI, Quantified

Tune a few assumptions and see the economics shift in real time.

ROI / Total Cost of Ownership

Wire-Bonding in MonoLith™

Understand where wire-bonding fits in the pack, and when we combine it with other joining methods.

- Decoupled development with low-heat interconnects

- Diagnostics to cell/board level; clean rework paths

- Hybrid strategy: wire-bond + laser where seams make sense

| Heat into cell | Low |

| Failure behavior | Redundant / compliant |

| Reworkability | High (bond-level) |

| QC methods | Pull/Shear + inline logs |

Customer Success Stories

Real-world deployments demonstrating MonoLith™ platform advantages across industries.

Aerospace Prototype Program

Challenge

Rapid iteration required for flight test vehicle with changing power requirements

Solution

MonoLith™ modular scaling allowed rapid iterations using same base modules

Results

- 3-month development timeline

- 225% cost savings vs custom approach

- Successful flight test program

Industrial Automation Fleet

Challenge

AGV fleet needed standardized power across 5 different vehicle types

Solution

Single MonoLith™ platform scaled from 25kWh to 150kWh across fleet

Results

- Unified maintenance procedures

- 50% reduction in spare parts inventory

- 99.7% uptime achieved

Defense Vehicle Program

Challenge

Mission-critical application requiring rapid deployment and field serviceability

Solution

MonoLith™ pack platform with comprehensive diagnostics and documented integration procedures

Results

- Faster bring-up with documented install & test

- Zero mission failures

- Exceeded MIL-STD requirements

MonoLith™ Battery System — FAQ

For executives (quick answers)

For engineers (the useful details)

Program & commercial

Straight talk

- If you need a UL-listed, road-legal pack next month, this isn’t it.

- If you need a credible pilot pack quickly—with a clean path to certs—this is exactly that.

- Lock cells/cooling/enclosure early; it saves months and five figures.

Getting started

- Duty cycle (CSV/plot), thermal constraints, envelope.

- Cell family (we’ll recommend from your load case).

- Required tests (UN38.3, EMC, vibe, IP).

- CAN map and connector set.

- Approve build sheet; we start cutting metal.

Ready to Experience the MonoLith™ Advantage?

Join industry leaders who have reduced their development costs by 75% and accelerated time-to-market with our patented platform technology.